CSAM Project

North Carolina Consortium for Self-Aware Machining and Metrology (CSAM)

Funded by the University of North Carolina General Administration

Current Main CSAM collaboration page

Previous CSAM collaboration page

About the project

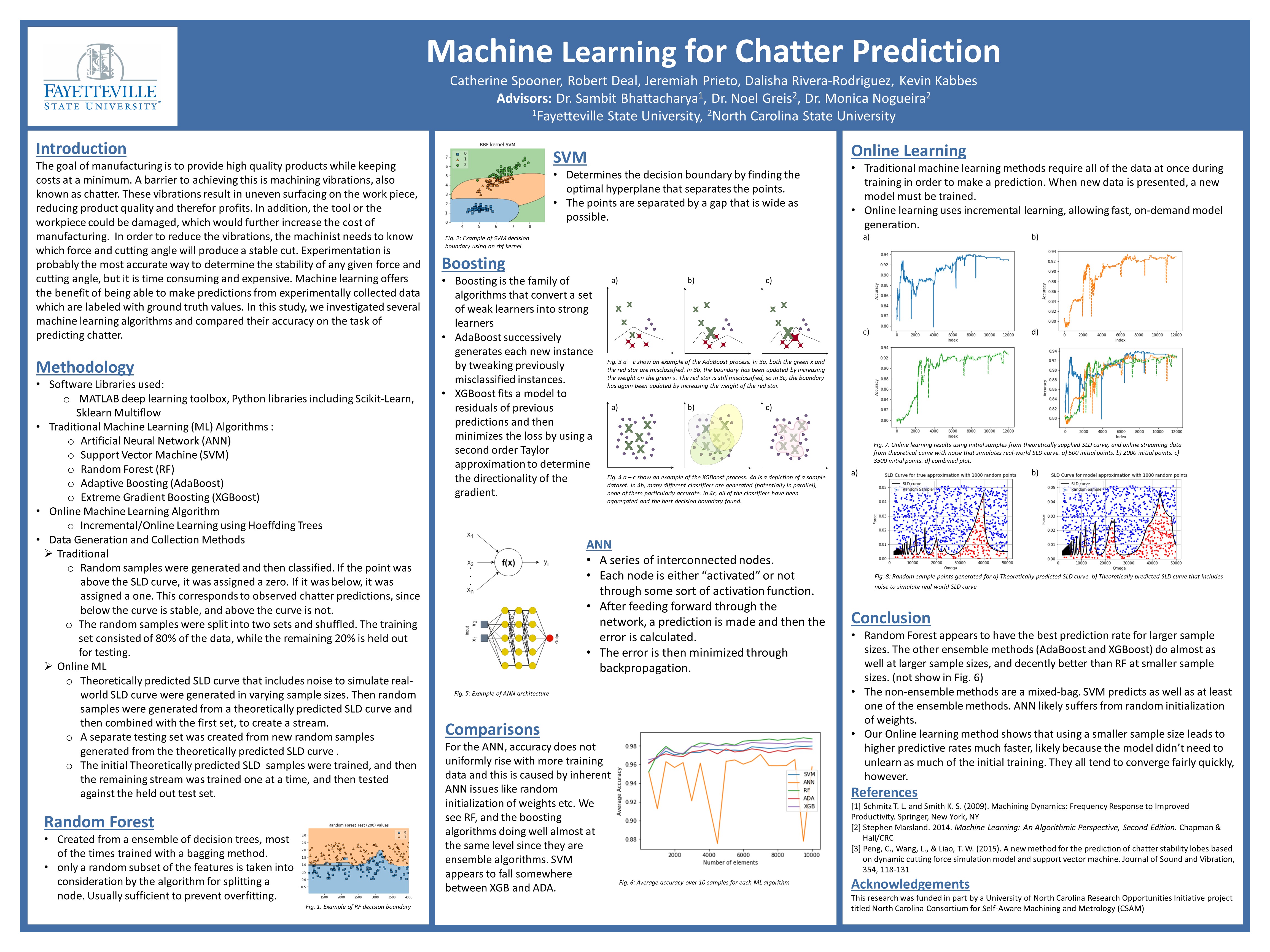

The overall goal of manufacturing is to provide high quality products in the most cost-effective way possible. The presence of chatter (instability) has shown to decrease the surface quality of a product, ultimately making the process more expensive for the manufacturer. Tool chatter is a function of force and cutting angle, and can severly impact the surface quality of a product. Chatter can also contribute to wear and tear on tool pieces themselves. Can we use data generated by an uncertain physics-based milling stability model (SLD) (Fig. 1) to train a machine learning (ML) stability model ("theory-based" ML model), and then update this model with experimental data to better approximate the "true" stability model, and therefore reduce uncertainty in parameter selection.

We have been investigating several updating strategies, as well as the machine learning algorithms used to make the predictions. The three machine learning methods that we are using in our investigations are an artificial neural network (ANN), support vector machine (SVM) and k nearest neighbors (KNN).

The updating strategies are climbing-the-hill, follow-the-curve and randomly generated. Fig. 2 and Fig. 3 demonstrate conceptual image of the first two strategies.

Figure 1: Hypothetical SLD Curve showing the stable region in teal, and the unstable region in white.

Figure 2: Climb-the-hill updating

Figure 3: Follow-the-curve updating

Students in the CSAM project:

- Robert Deal

- Kevin Kabbes

- Joshua Hilbish

- Adam Rash

- William Flathmann

- Dominic Proctor

- Yuan Gao